FMO | FM DESIGN | HVAC SYSTEMS MAINTENANCE EL

HVAC&R SYSTEMS MAINTENANCE

|

| FM SYSTEM DESIGN |

ASHRAE Handbook “HVAC

Applications”, defines repair as to

make good or to restore to good or sound conditions and, defines service as what is necessary to effect a maintenance

program short of repair.

HVAC&R maintenance is: “the part and labor” costs, required to maintain or restore HVAC&R systems to condition such that they can be effectively operated to meet specified performance.

In the ASHRAE Handbook, maintenance

also is classified into the

following categories:

1. Run to failure: a kind of

arrangement such that no money is spent on maintenance prior to equipment or

system breakdown.

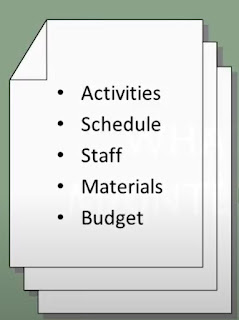

2. In planned maintenance: all

functions and resources in this category must be planned | budgeted |

scheduled. Can be divided:

a. Preventive

action: a kind of scheduled maintenance for an HVAC&R

system, equipment or components in order to maintain durability – reliability –

efficiency and safety.

b. Corrective

action: is often the remedial action performed before

failure occurs. In case it happens during a shutdown in response to a failure

is called a repair.

3. Predictive maintenance: is based on

equipment and systems monitoring the operating conditions and performance to

discover faults and degradations and thus the remedy performed.

Most manufacturers give detailed

instructions in how to operate and maintain the specific equipment and instruments.

These instructions must be followed.

Maintenance Contractors and Maintenance Personnel

In most small facilities with comparatively

simple HVAC&R systems outside maintenance contractors often provide maintenance

service based on the specified maintenance program.

The time interval between two maintenance

programs depends on the operating hours of the HVAC&R system, that is:

1. Dirt

accumulation the filters.

2. Coils.

3. Distribution

devices.

4. Recalibration

requirements of the instruments.

For

small and complicated HVAC&R systems whenever the operator cannot repair

and service the system, the Owner or the facility manager should ensure that

qualified contractors are hired for maintenance.

For

more complicated medium sized multizone systems operating personnel are often

responsible for HVAC&R. The maintenance programs should de detailed in the

O&M manual and tailored to each specific building. For high technical

equipment and systems an outside maintenance contractor with the specific

expertise required should be called for service.

For

large HVAC&R systems with central plants, a management organization with

one operations person and one maintenance person is required. Computerized

maintenance programs should be used to provide detailed timing of system maintenance

procedures.

Logged

information and proper data management associated with predictive maintenance will

reduce failure response requirements. An outside maintenance service contractor

with specific expertise may need to be called.

Monitoring and Fault Detection and Diagnostics Assisting Predictive Maintenance

Faults occur when the actually

measured parameters deviate from the normal operating values.

Performance degradation is an

evolving fault accumulated during a certain period of time.

By using:

a. Rule-based

expert systems, &

b. Autoregressive

with exogenous inputs, &

c. Artificial

neural network models,

then Performance degradation and

faults can be determined.

HVAC&R maintenance is an

important part to improve IAQ and to maintain a safe, healthy and comfortable

indoor environment.

Σχόλια

Δημοσίευση σχολίου